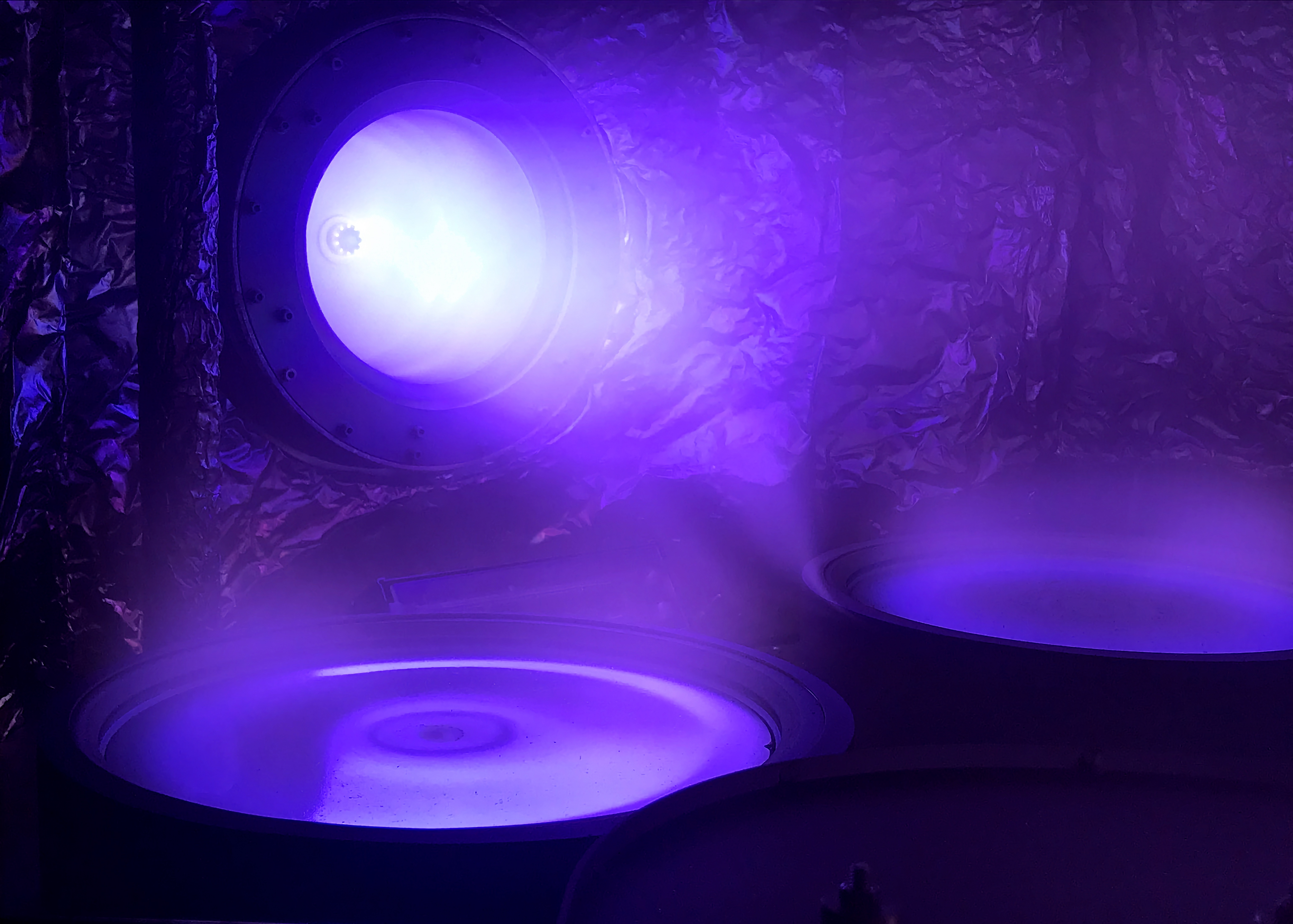

Plasma Assisted Reactive Magnetron Sputtering (PARMS) system

Vacuum system Meridian is an effective system for high-rate deposition of high-precision optical coatings for a wide range of applications. Meridian system helps to obtain thin films of a variety of materials with high accuracy and excellent quality. Optical control allows to make the processes fully automatic and increase the yield significantly.

Key benefits:

- Long throw sputtering configuration enabling particle free coating processes

- Sputter-Up configuration

- High-yield dual-magnetron AC sputtering systems

- Long life RF plasma sources for precleaning and assisting

- On-substrate direct Optical control system I-Photonics OCP

- Double rotation planetary substrate holder allows mounting of different substrate sizes (200, 250 and 300mm)

Applications:

- Ultra narrow band pass filters

- Multizone filters

- Steep-edge filters

- Single- and multi-notch filters

- Laser mirrors

- Thin-film polarizers

- Beam splitters

Technical data

| Sputtering source | HY planar circular magnetrons |

| Assisting source | RF plasma source Copra DN250 CCR |

| Capacity | Dual rotation planetary holder 10 x 200 mm |

| Coating uniformity | <+/-0.2% |

| Sputtering materials | Ta2O5, SiO2, HfO2, Al2O3, Nb2O5 |

| Coating rate | Up to 6 A/sec (material dependent) |

| Control system | Automatic optical control system I-Photonics OCP |

| Process temperature | <250 oC |

| Pumping system | Dry mechanical pump Turbomolecular pumps |

| Ultimate pressure | 8e-4 Pa |

| Time to reach start process | 45 min |

| Installation area (LxWxH) | 3790x3560x2450 mm |

| Equipment weight | 3400 kg |